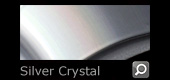

Attractive commodity group that doesn't permit other follows

|

|

|

|||||||||

|

|

|

|||||||||

|

|

|

|||||||||

|

|

|

|||||||||

|

|

|

|

|

|

||||||

DISK Finish>>

¡Balkën Brushed

"Brushed" processed in round shape for the first time in this industry. In Balken, it was named "Balken Brushed" with pride. Leaf brushed that reaches hundreds of pieces of 30milli-meter in the diameter is deliberately performed to the whole face one by one by the skilled craftsman's hand work. The difference with leaf brushed on the surface stands out by shooting a bitter, slow light by the sanding (polish with minute sand) on the hall side.¡Super Brushed

The quality feeling in a peculiar bare skin feeling by the forge and the machining processing was finished more coolly and brightly by having a lot of processes, a buff processing added to the hall edge part of a normal Brushed processing. It is exactly completion of suitable Brushed for calling super.¡Silver Crystal Cut

Forged skin that is pressed by pressure of 8000 tons and generated is exact, has very excellent brilliance, and becomes another dimension with forged skin. In Balken, to dare to at the height of the forge to classify with the polish used for the casting commodity, EEE It was named that it crystallized. The difference of the shine is obvious.¡Balkën Black

Anodized color and produces a surface oxide film of aluminum anode during electrolysis will be strong, and the surface treatment method of applying a coating to produce electrolytic coloring, spray paint and aluminum wheels is usually used different.Listen closely to the nature of anodized aluminum, the finish should be stable and smooth surface ... Which can be adopted because it has improved performance forged aluminum disc that is. By using this special colored surface treatment can significantly improve the wear resistance and corrosion resistance of aluminum itself. And spray paint and above all is a big visual difference. Black anodized top surface of the disk is directed to exactly the height of craft and express the world of luxury jet filled with a deep luster and texture very similar to the coats of lacquer. In addition to the disk side of the sanding process (tasks such as filing and polishing the surface) are strong and tightens the entire wheel and a strong complement to more exquisite contrast of black anodized aluminum top panel by the dull glow of cool.

¡Shot Anodized Mat Black

Shot peening, while forming a dimple fine disk surface by projection on the disk by mechanical forces also air the material projection, including steel ball little to improve the fatigue resistance and durability and a uniform surface stress Surface Treatment. In addition, the unique forging process by adding a colored anodized dramatically improved wear resistance and corrosion resistance of aluminum itself "depth" is expressed in the design of an exquisite combination of matte black top surface and dimples appeared crowded off the chic shades, and achieved only look super cool unmatched.¡Brushed Anodized Mat Black![]()